Check it out here:

About this item

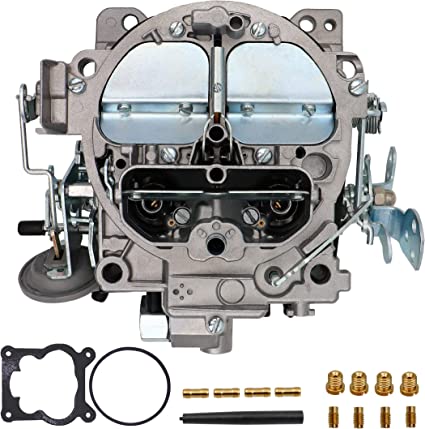

- Replace Part Number: Directly replacement 4-BBL carburetor Replace For 1901-GG Rochester Quadrajet Carburetor- 4MV - 1966-1973, 1975-1979 Corvettes,1968-1973 Chevy/GMC Trucks Part Number 1901R. Interchange with Chevy 7026202 7026203 7026210 7027202 7027203 7027212 7027213 7040007 7040021 7046904 7047207 7047303 7047305 7047306 7047307 7047316 7047319 17054236 17054709 170549.

- Fitment: Carburetor Fits For Carburetor For 1901R Rochester Quadrajet 4MV,Directly replacement 4-BBL carburetor compatible for 1966-1973 Chevy 327-454c.i, 1975-1979 Corvettes, 1968-1973 Chevy/GMC Trucks Part Number 1901R.

- This Universal Performance carburetors improve throttle response and overall performance throughout the RPM range. Each carb has a distinctly different fuel curve calibrated for a particular application. Do note: Condering the vehicle dispacement range discrepancy, some vehicles may be too rich with black smoke from the muffler, You may have to use The included tool and small copper solid pin to block the air channels to fix it, If you are confused, Message us before any adjustment

- 1 Year Warranty: This item has 1 year warranty. In the event the item should fail due to manufacturing defects during intended use, we will replace the part by free.We recommend that you search for relevant installation videos on the Internet and follow the correct steps strictly. Product does not include installation instructions.

- Customer Service:This Item comes as shown in the picture.Please check pictures for more details.If you are uncertain about the item, feel free to contact us for confirm.Before purchase, please check carefully whether the carburetor you need to replace is the same as this product. We recommend that you search for relevant installation videos on the Internet and follow the correct steps strictly. Product does not include installation instructions.

FITMENTS:

Fitment: Carburetor Fits For 1970-1972 V8 Chevy big block Mark IV 6.6L/402 Carburetor Fits For 1967-1973 V8 Chevy small block Gen I 5.7L/350 Carburetor Fits For 1966-1970 V8 Chevy big block Mark IV 6.5L/396 Street Carburetor Fits For 1966-1969 V8 Chevy small block Gen I 5.4L/327 Street Carburetor Fits For 1966-1969 V8 Chevy big block Mark IV 7.0L/427 Street Carburetor Fits For 1970-1973 V8 Chevy big block Mark IV 7.4L/454 Carburetor Fits For 1970-1973 V8 Chevy small block Gen I 6.6L/400 Carburetor Fits For GMC 1967-1968 V8 Chevy small block Gen I 5.4L/327 Carburetor Fits For GMC 1968-1969 V8 Chevy big block Mark IV 6.5L/396 Carburetor Fits For GMC 1969-1973 V8 Carburetor Fits For Chevy small block Gen 5.7L/350 Carburetor Fits For GMC 1970-1973 V8 Chevy big block Mark IV 7.4L/454 Carburetor Fits For GMC 1971-1972 V8 Chevy big block Mark IV 6.6L/402. Replaces Part Numbers: Directly replacement 4-BBL carburetor Replace For 1901-GG Rochester Quadrajet Carburetor- 4MV - 1966-1973, 1975-1979 Corvettes,1968-1973 Chevy/GMC Trucks Part Number 1901R. Interchange with Chevy 7026202 7026203 7026210 7027202 7027203 7027212 7027213 7040007 7040021 7046904 7047207 7047303 7047305 7047306 7047307 7047316 7047319 17054236 17054709 170549.

GENERAL DESCRIPTION

The Quadrajet is a 4-barrel two stage carburetor of down-draft design.Its simplicity in construction makes it easy toservice, yet its versatility and principles of operation make itadaptable from small to very large engines,without majorcasting changes.

There are three separate basic carburetor models. They aredesignated as 4M,4MV, and 4MC. The 4M is the basic car-buretor equipped for manual choke operation.The 4MV isan automatic choke model designed for use with a manifoldmounted thermostatic choke coil.The 4MC model is an auto-matic choke carburetor which has the choke housing and coilmounted at the side of the float bowl. Except for chokesystems,all models have basically the same principles ofoperation.

FLOAT SYSTEM

The Quadrajet carburetor is unique in that it has a cen-trally located fuel reservoir (fuel bowl). The fuel bowl iscentered between the primary bores and is adjacent to thesecondary bores. This type design assures an adequate fuelsupply to all carburetor bores, which results in excellent per-formance with respect to car inclination or severity of turns.

The float pontoon is solid and is made of a light closedcell plastic material. This feature gives added bouyancywhich allows the use of a single float to maintain constantfuel levels.

There are two types of float needle valves used in theQuadrajet carburetor. One type is diaphragm assisted and theother is the standard needle and brass seat.

The diaphragm assisted float needle is primarily used witha smaller float and on engines equipped with high pressurefuel pumps. The needle seat is a brass insert and is pressed into the bowl fuel inlet channel below the diaphragm needletip. The seat is not removable, as the needle valve tip is of amaterial which makes seat wear negligible. Care should beused during servicing so that the seat is not nicked, scored ormoved.The float valve is factory staked and tested andshould not be re-staked in the field.

On most models, a fuel inlet filter is an integral part of thefloat bowl and is located behind the fuel inlet nut. Shouldthe filter become plugged due to excessive dirt or improperservice, a pressure relief spring located behind the filter element allows fuel pump pressure to force the element off itsseat. This allows fuel to by-pass the filter and enter the car-buretor so the engine will run until the filter can be serviced.It is very important that the filter be serviced periodically toprevent dirt from entering the carburetor metering orifices.

The float system (Figure 2) consists of a fuel chamber(float bowl), a single pontoon float, float hinge pin and re-tainer combination, float valve and seat and a float valve pullclip. A plastic filler block is located in the top of the floatchamber over the float valve to prevent fuel slosh into thisarea.

The float system operates in the following manner: Fuel

from the engine fuel pump enters the carburetor fuel inletpassage. It passes through the filter element, fuel inlet valve

and on into the float bowl chamber. As the incoming fuelfills the float bowl to the prescribed leve1, the float pontoonrises and forces the fuel inlet valve closed, shutting off fuelflow. As fuel is used from the float bowl, the float dropsallowing the float needle valve to open, allowing more fuel toagain fill the bowl. This cycle continues, maintaining a con-stant fuel level in the float bowl.

A float needle pull clip, fastened to the float needle valve,hooks over the edge of the float arm at the center as shownin Figure 2. Its purpose is to assist in lifting the float valveoff its seat whenever fuel level in the float bowl is low.

Fuel flow through the diaphragm assisted float needle

valve varies from the standard float needle. With the standardtype as shown in Figure 2 fuel flows from the inlet filter andinlet channel up through the needle seat orifice past the float

needle valve and spills over into the float bowl. With thediaphragm type float needle valve (see inset) Figure 2 fuelfrom the inlet filter enters the channel above the float valvetip. When fuel level is low in the bowl the neeale vaive 1s onits seat and fuel flows down past the float valve tip into a

fuel channel which leads upwara tnrougn ule ouw itas theto a point above normal liquid level ana sps oyei nnn ufloat bowl.

The diaphragm type needle valve has some advantagesover the standard float needle in that a larger needle seat

orifice can be used to provide greater fuel rlow to tne 1oatchamber and yet allow the use of a small float. This is accom-

plished through a balance of forces acting on the float needlevalve and diaphragm against fuel pump pressure. Fuel pres-

sure entering the float needle valve chamber tends to forcethe needle valve closed. However, the same pressure is alsoacting on the float needle diaphragm. The diaphragm has aslightly larger area than the float needle valve head, there-fore,the greater pressure acting on the diaphragm tends topush the needle valve off its seat.The force of the float armacting on the needle stem, as the float bowl fills, overcomesthis pressure difference and closes the needle valve.There-fore, the float's function is to overcome the pressure difference and does not have to force the needle valve closedagainst direct fuel pump pressure.

The carburetor float chamber is internally vented on allmodels through two vent tubes located in the air horn.Theinternal vent tubes lead from beneath the air cleaner to thefloat bowl chamber.Their purpose is to balance air pressureacting on the fuel in the bowl with air flow through thecarburetor bores.In this way, balanced air/fuel mixture ratioscan be maintained throughout all carburetor ranges of opera-tion.

Some engine applications require an external vent into thefloat bowl during hot engine operation. The Quadrajet floatbowl is externally vented through an idle vent valve.Its pur-pose is to vent fuel vapors which may form in the float bowlduring periods of hot engine idle and "hot soak”.

In operation the idle vent valve is closed except when thethrottle valves are in the idle position, When the throttles areclosed a wire lever on the pump lever pushes upward on thespring steel vent valve arm and opens the vent valve. Thus,fuel vapors are allowed to vent externally,thereby pre-venting them from entering the carburetor bores and beingdrawn into the engine.This prevents rough engine idle andexcessively long hot engine starting.

When the throttle valves are opened to the off-idle andpart throttle position, the idle vent valve closes, returning thecarburetor to internally balanced venting.

IDLE SYSTEM

The Quadrajet carburetor has an idle system on the pri-mary side (fuel inlet side) of the carburetor to supply thecorrect air/fuel mixture ratios during idle and off-idle opera-tion. The idle system is used during this period because airflow through the carburetor venturi is not great enough toobtain efficient metering from the main discharge nozzles.

The idle system is only used in the two primary bores ofthe carburetor. Each bore has a separate and independentidle system. They consist of idle tubes, idle passages, idle airbleeds,idle channel restrictions,idle mixture adjustmentneedles and idle discharge holes.

During curb idle the throttle valve is held slightly open bythe idle speed adjusting screw. The small amount of air whichpasses between the primary throttle valve and bore is regu-lated by this screw to give the engine the desired idle speed.Since the engine requires very little air for idle and lowspeeds, fuel is added to the air to produce a combustiblemixture by the direct application of vacuum (low pressure)from the engine manifold to the idle discharge hole belowthe throttle valve. With the idle discharge holes in a very low pressure area and the fuel in the float bowl vented to atmo-sphere (high pressure), the idle system operates as follows:Fuel flows from the float bowl down through the mainmetering jets into the main fuel wells. It is picked up in themain wells by the two idle tubes (one for each primary bore)which extend into the wells.The fuel is metered at the lowertip of the idle tube and passes up through the tubes. On somemodels, where needed, the fuel is mixed with air at the topof each idle tube through an idle air bleed. The fuel mixturecrosses over to the idle down channels where it is mixed withair at the side idle bleed located just above the idle channelrestriction. The mixture continues down through the cali-brated idle channel restrictions past the lower idle air bleedsand off-idle discharge ports where it is further mixed withair.The air/fuel mixture moves down to the adjustable idlemixture needle discharge holes where it enters the carburetorbores and blends with the air passing the slightly open throt-tle valves. The combustible air/fuel mixture then passesthrough the intake manifold to the engine cylinders.